| Payment Type: | L/C |

|---|---|

| Incoterm: | FOB,CIF |

| Delivery Time: | 15 Days |

Model No.: Customized

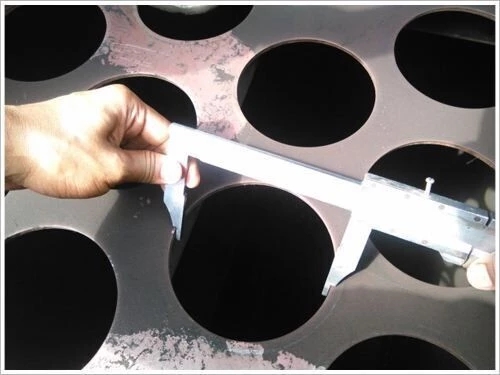

A skeleton steel wire: a steel wire perpendicular to the filter bag

Product requirements

The surface of the galvanized dusting skeleton and the filter bag should be smooth and smooth, not allowed to have welding scars, bumps and burrs, so that the dust filter bag passes through the strong wind pressure of the main fan of the dust collector and the repeated blowout of the dust of the air cleaning machine and the blowing air of the pulse valve. The rubbing will not be damaged.

Service life

The dust skeleton is the rib of the filter bag. It should be light and easy to install and maintain. The quality of the frame directly affects the filtering state and service life of the filter bag. The natural granite is used to process the circular curved plate through mechanical processing. The whole structure is smooth and smooth. It has the characteristics of corrosion resistance, abrasion resistance and high temperature resistance. The exterior is poured with high strength and high temperature resistant and alkali resistant materials. The strength and life span of the equipment are greatly enhanced by the outer protective steel plate of the barrel equipment. The body uses 1 meters per section structure, the joints have concave and convex joints at each joint, and the joints are connected with furan resin or acid alkali glue mud at the joint to ensure that the connection is not leaky; overcoming the common faults of the seeping and air leakage of the original granite duster. The upper sink. For the ceramic structure, the ceramic dust collector ensures no water leakage in the water supply process, avoids the seepage setback of the original granite duster water trough, and strengthens the use effect of the dust collector. The simple installation is 1 meters per day, and the site can be installed for half a day, reducing the construction period.

Product Categories : Dust Collector Fittings > Dust Collector Bag Cage