Product Description

Model NO.: Q47 Connection Form:

Flange Nominal Pressure: PN1.0-32.0MPa Structure: Fixed

Ball valve Function: Blow-Down Valve Application: Industrial Usage, Water Industrial Usage Place of Origin: Zhejiang Transport Package: Seaworthy Plywood Case Origin: Wenzhou, China Material: Wcb Driving Mode: Pneumatic Channel: Straight Through Type Type: Fixed

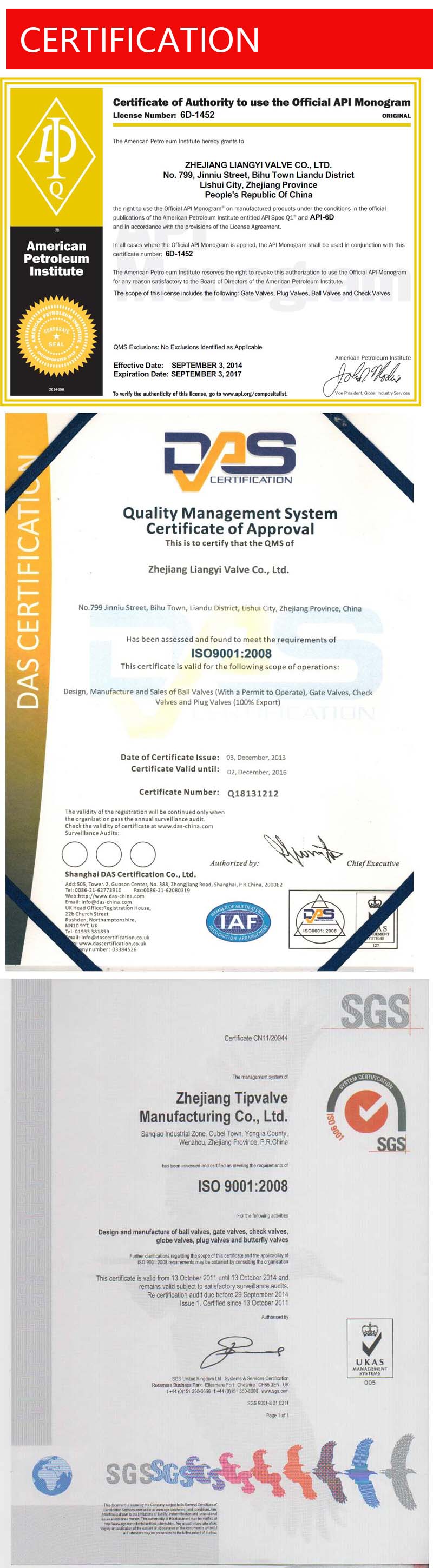

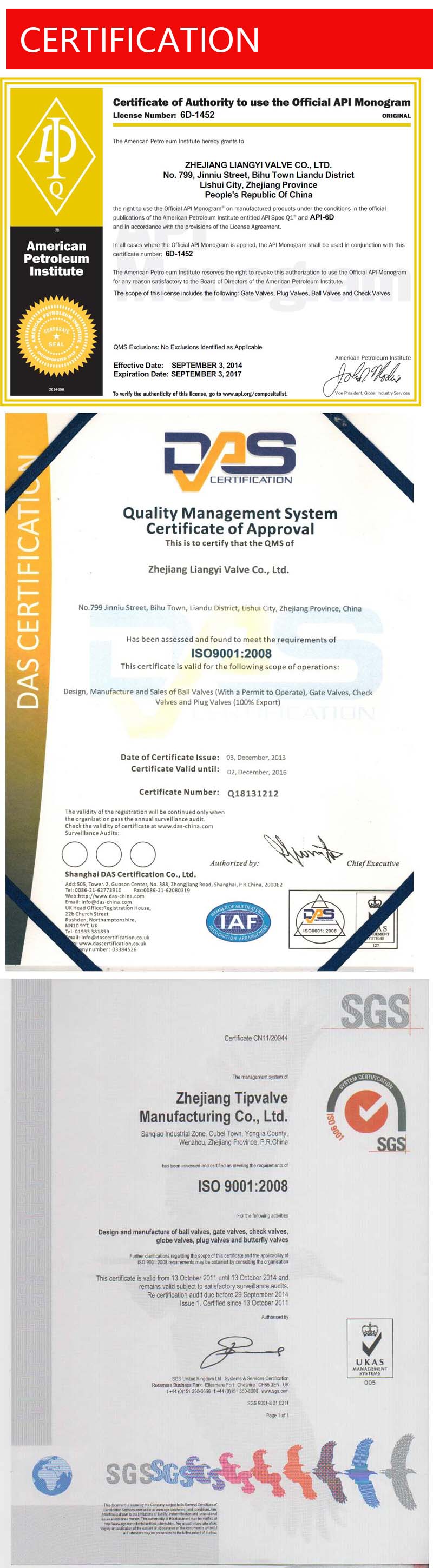

Ball Valve Temperature: Normal Temperature Size: 2"-48" Trademark: LYV, OEM Specification: CE, ISO, API HS Code: 8481804090 Worm

GEARBOX Flanged Cast Steel Ball Valve

Specifications ball valve: Fluid resistance small,Simple structure, small volume, light weight.fine seal,easy Operate and maintenance,wide use 3 PC Forged Steel ball valve: They are supplied for a broad range of applications in the power generation, chemical and petrochemical, oil and gas, pulp and paper,mining, and ship-building industries A.Forged ball valve feature LIANGYI forged ball valve,the forging material can ensure sufficient rigidity and strength under maximum rated operation pressure without inherent flaw of cast. Enough wall thikness of separate body and adaptation of high strength tie bolts are convenient for valve maintenance and sufficient to bear the stress of pipe.The internal parts of valve are carefully designed and selected to ensure reliability under all kinds of work condition. B.Anti-fire safe design When the trunnion ball valve be used normally,its sealed by seat and ball surface,seat retainer sealed by O-ring and body,this is soft sealed and reliable sealing.When the seat and O-ring are burnt,the seat retainer and body will be sealed by expanded graphite.Thus act anti-fire safe purpose. C..Anti-static device In order to prevent friction among ball,stem and PTFE that generates static electricity which may light the combustibles and explosives that cause an accident,in this ball valve,static-conduction spring is set between the stem and the ball,the stem and the body.Thus static electricity is conducted to ground and system safety is secured. D.Free leakage of body Sealed construction The connective position of valve body and bonnet is double sealed by gasket and O-ring,on this base,such factors as fire,high temperature,shock and uneven opening or closing of the torque all can't induce external leakage. E.Low torque in operation The self-lubricated bearings are installed at the friction of stem,resulting in wear resistance,fiexibility of operation and low torque. F. Double block&bleed(DBB) When ball is full open or close position,the transmitter substance in center cavity of body can be released by drainage and emptying devices.In addition,the over loaded pressure in the center cavity of valve can be released to low pressure end by self relief seat. G.Emergency sealing Compound injection holes are designed and compound injection valves are installed at locations of stem/cap and body support of side valve.When sealing of stem or seat is damaged to induce leakage,the compound can be used to do the second time sealing.A concealed

Check Valve is installed in side of each compound injection valve to prevent compound from out flowing due to the action of transmitter substance.The top of the compound injection valve is the connector for fast connection with compound injection gun. H.Extension stem For the underground installed valve,the stem can be lengthened and for the convenience of operation the corresponding compound injection nozzle and drainage valve can be extended to the top of valve. I.Automatic body cavity relief When the body pressure going up un-normally as the unstable factor,the trunnion ball valve downstream seat will be pushed by unnormal pressure,and the release the un-normally pressure automatically,it doesn't damage to the sealing of upstream seat. J.Various driving types The top pad of valve designed according to ISO 5211,which is convenient for connection and exchange of various drivers.The common driving types are manual,electrical,pneumatic and pneumatic/hydraulic working condition: working temperature:-30 °C~570 °C Working temperature:1.6~42mpa media: W.O.G(Water,gas,Oil)

| PRODUCT | SIZE | PRESSURE | ORIGIN | TEMP. |

| FORGED BALL VALVE | 2"-48" | 150LB-1500LB | ZHEJIANG | NORMAL |

Contact us if you need more details on Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ball Valve、Carbon Steel Ball Valve. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Ball Valves

Contact us if you need more details on Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ball Valve、Carbon Steel Ball Valve. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ball Valve、Carbon Steel Ball Valve. If these products fail to match your need, please contact us and we would like to provide relevant information.